Manufacturing > Quality policy

Manufacturing > Quality policyQuality policy

“Continuous quality control with a quality policy and management system”

KODACO will realize customer satisfaction with continues quality innovation and substantial management to reward customers’ expectation. KODACO is doing its best for management such as quality innovation, improvement, control and assurance by focusing on securing competition priority through quality.

Quality management system

- [ISO/TS 16949]

- Developed by IATF(International Automotive Task Force) and approved and issued as an international standard by ISO(International Standardization Organization)

- IATF was formed through participation of 3 big U.S. auto makers(Daimler Chrysler, GM, Ford), European auto makers(Peugeot, Renault, Volkswagen, Flat, BMW, etc.), U.S. and European auto associations, etc.

- Born as a global standard integrating Europe and U.S. differently from QS-9000 developed by 3 big U.S. auto makers as the auto related quality system requirements(design, development, production, installation and service)

- Born as a single international technology standard by integrating the quality assurance system as an ISO technology standard

- Satisfaction of customer requirements with a single examination for the enterprises transacting with both Europe and U.S.

- [ISO-9001]

- The ISO 9000 series(quality management standard) means an international standard for quality management and quality assurance for suppliers.

Under the situation in which the world economy is globalized, the concepts of quality assurance are different from each other depending on nations and organizations(enterprise, etc.).

Accordingly, the ISO 9000 series was established to prevent the free circulation of products and services from being disturbed.

As mentioned above, this standard is largely affected by the concept and habit of Europe and U.S. based on British BS 5750.

Therefore, this has features such as contract principles, manual preparation, attaching importance to verification, system orientation, etc.

- The ISO 9000 series(quality management standard) means an international standard for quality management and quality assurance for suppliers.

- [ISO-14000]

- What is ISO 14000 series?

The environmental management certification system is an international environment assurance standard that evaluates the environmental control system and its management results and decides a guideline for the environmental control technology contributing to continuous development in order to minimize the effect of actual production activity of Green Round for real requirements on the environment. -

Necessity of ISO certification

– Improvement of environmental performance and environmental condition

- Conservation and reduction of introduce raw materials and energy

- Promise of verifiable environmental control to customers

- Reduction of accidents through establishing a responsibility limit

- Maintenance of good social relationships

- Promoting technical development and sharing a solution to environmental problems

- Promotion of organizational image and market share

- Maintenance of improved relationships between government and enterprise

- Improvement of cost control

- What is ISO 14000 series?

- [SQ certification]

- This is a SUPPLIER-QUALITY certification system made to produce and supply the best product eventually by stabilizing a production quality system between processes by focusing on the type of business whose durability is difficult to confirm as a complete product. The type of business is rubber field(raw rubber, CMB sales, rubber molding), electric component(W/H), casting and forging, electric and electronic component, welding, heat treatment, injection, sewing, painting, plating, etc.

In order to acquire this quality certificate, you should have transaction results with Hyundai and Kia Motors, and the SQ examination shall be carried out by focusing on production and quality as a site-focused examination differently from the ISO, QS, TS examinations.

- This is a SUPPLIER-QUALITY certification system made to produce and supply the best product eventually by stabilizing a production quality system between processes by focusing on the type of business whose durability is difficult to confirm as a complete product. The type of business is rubber field(raw rubber, CMB sales, rubber molding), electric component(W/H), casting and forging, electric and electronic component, welding, heat treatment, injection, sewing, painting, plating, etc.

Quality requirement system

The goal of KODACO’s omnidirectional quality management system is to secure the initial quality and improve quality substantially.

- Analysis and securing of production capability

- Confirmation of initial products

- Statistical process control : The mass production process is used as the basic data for quality mass analysis and improvement activity by using a statistical process control technique.

- Continuous improvement activity

- Establishment of a Fool Proof System

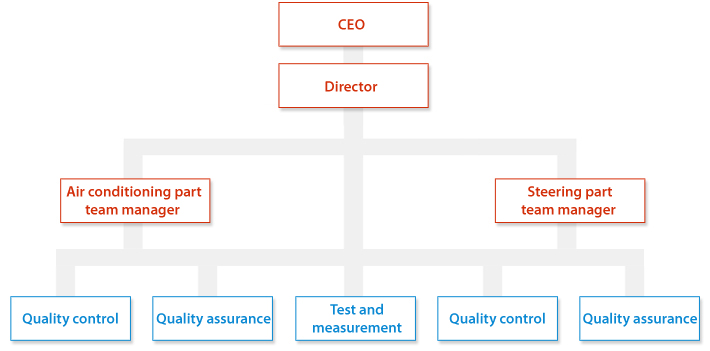

Quality assurance organization chart

Quality assurance equipment situation

| No | ITEM | MAKER/SPECIFICATION | Q’TY |

|---|---|---|---|

| 1 | CMM | Sheffield (750x625x500) | 2 |

| IMS (1100x1100x750) | 1 | ||

| 2 | Spectrometer (Emmision) | Shimadzu (Al, Zn) | 2 |

| 3 | X-ray | Philips (MU15FL) | 2 |

| 4 | Perthometer Concept Surface & Contour | MAHR | 4 |

| 5 | Hardness | Rockwell | 2 |

| 6 | Electromechanical Universal TestMachine | Korea | 1 |

| 7 | Digital Height G/G | TESA (0-600mm) | 6 |

| 8 | Hole Tester | 2 ~ 100mm | 20 |

| 9 | Digital Macrometer | 1 ~ 100mm | 20 |

| 10 | Height Gage | 0 ~ 600mm | 7 |

| 11 | Stone Surface Plate | 1000 x 1000mm | 2 |

| 12 | Pin Gage | 1.550 ~ 15.300mm | 9 sets |

| 13 | Infrared Thermometer | 1 | |

| 14 | Air Micrometer Set | MERCER (EL400) | 1 |

| 15 | Thread Gage | 50 | |

| 16 | Calibrtion Tester | 0-25mm / 0.001mm | 1 |

| 17 | Block Gage | 103 PCS (Grade 0) | 1 |